GUIDE BUSHES AND BALL CAGES

Guide elements from the german brand Steinel Normalien GMBH. We have seven types of Guide bushes: steel sliding guide bronze plated, ball guide aluminium, brass and plastic, roller guide, sliding guide with solid lubricant and sliding guide with solid. lubricant bands..

Exchange bushes

Thanks to their single seat diameter, all bushings can be interchanged with each other. A support with a sliding or roller guide can be modified without additional work. Only the guide bushings have to be changed. Depending on the housing diameter, the following can be used: two different guide diameters, seven types of guide, three types of bushing (with flange, flanged or smooth) and three bushing lengths. As a result, it is possible to select between 126 guide bushing combinations for each seat diameter.

In the following links you will find the different types of bushings, as well as an assembly guide for the bushings and ball cages:

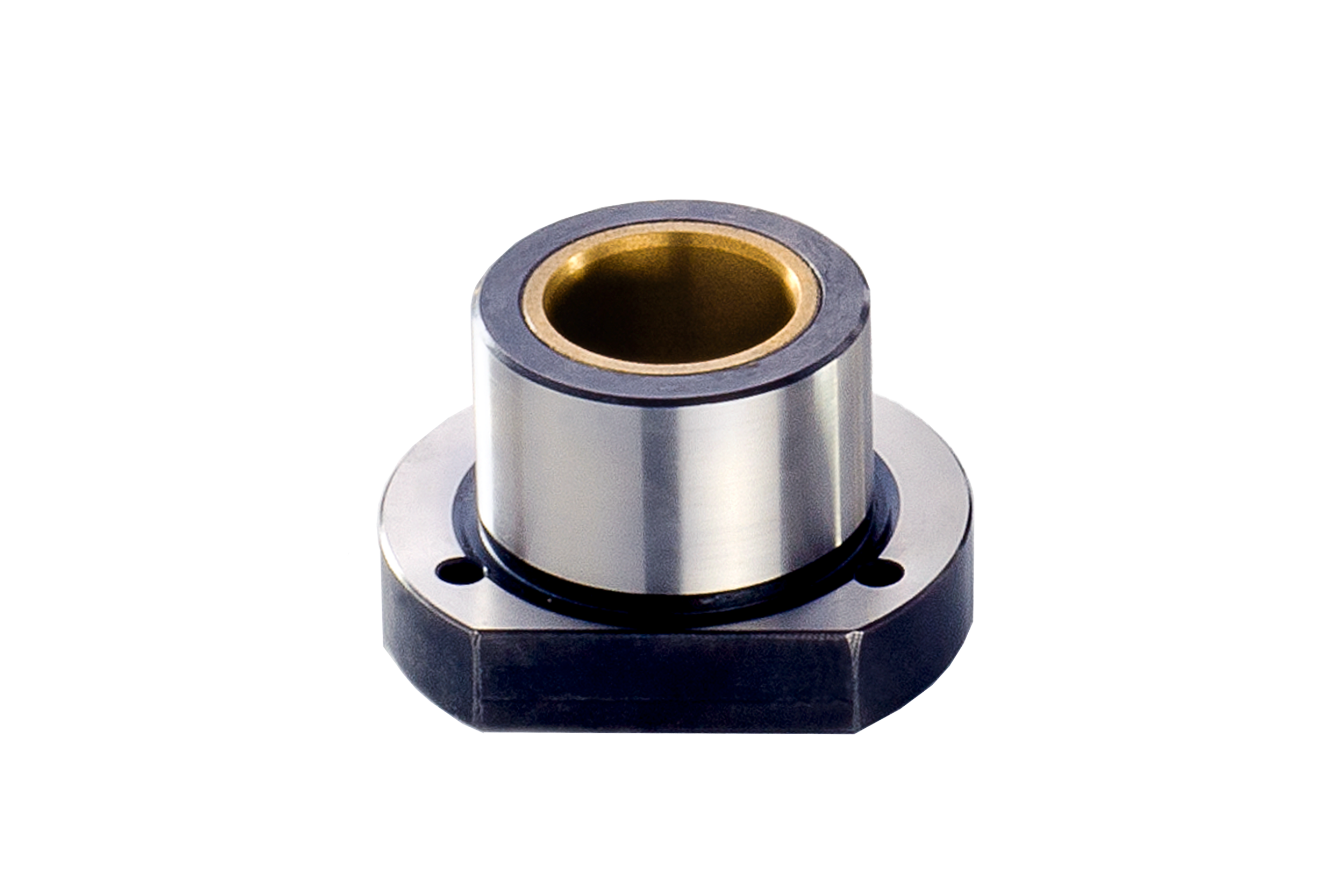

Sliding guides, steel with bronze coating

The hardened steel body (63 HRC) takes on lateral forces

and prevents the guide bush from becoming deformed

due to the strong force application.

The galvanic bronze layer spread across the running

surface is very hard (250 – 300 HV), extremely low-wear

and honed to the highest surface quality. In the following link you will find the catalog:

Bronze coated steel guide bushing

Apart from its excellent emergency slip property, it has excellent thermal conductivity in order to quickly dissipate the resulting friction heat.

The guide bush’s internal lubrication system consists of parallel lubrication grooves which are joined via connecting grooves. The design of the internal lubrication system guarantees an even distribution of lubricant on the entire sliding surface and provides an effective shielding against dirt.

Bronze coated steel guide bushing. The recommended sliding speed is 15-20 m/min. These optimally dimensioned lubrication guides allow even extremely high speeds of 600 to 800 strokes/min.

Guide bushing with solid lubricant

Our lubrication-free and maintenance-free guide bushings are complex, highly wear-resistant and highly precise sliding elements. In sliding movements, the solid lubricant causes the formation of a continuous and firmly adhered film between the guide elements. This film remains adhered to the sliding surfaces also during stopping or starting, thus preventing a seizure between the bushing and the guide column. In the following link you will find the product catalogue:

Guide bushing with solid lubricant

Powdered raw materials, such as graphite, molybdenum disulfide, bronze powder and lubricant, are mixed into certain compositions and subsequently sintered. The maximum sliding speed is 20 m/min.

Bronze guide bushing with solid lubricant rings

Like the previous family, these lubrication-free and maintenance-free guide bushings are complex sliding elements, highly resistant to wear and with maximum precision. They are made of bronze and contain solid lubricant rings inside, which cause the formation of a continuous and firmly adhered film between the guide elements. In the following link you will find the product catalogue:

Bronze guide bushing with solid lubricant rings

Lubrication with solid lubricant is produced by particles of solid matter, whose crystalline structure shows a reduced resistance to cutting and, being between two surfaces, fulfills the function of lubrication. The maximum sliding speed is 20 m/min.

Precision ball guides

Steinel ball guides or roller guides have high precision thanks to highly accurate sliding surfaces and precision steel balls with the same classification. The balls are free-running and arranged in a spiral in the axial direction, in such a way that each ball has its own raceway, providing a long useful life. Thanks to the exact size of the balls and the fact that they are pre-stressed, we achieve guidance without play and maximum precision. In the following link you will find the ball cage catalog:

Ball guides

The radial resistance of the ball guide increases with the prestressing, while the ease of sliding decreases. However, if the prestress is too high, the guide is overloaded due to too high a surface pressure. For this reason, the prestressing must be from 4 to 14 µm depending on the diameter of the guide. These guides allow travel movements of 30-40 m/min and even higher.

Some additional features of our ball cages are: the possibility of having a fixing lock that holds the cage to the guide column; incorporate a limiting sleeve or stop for the travel of the cage and the almost zero maintenance that they require, in which adequate lubrication in the assembly is enough to guarantee a long life.

We have several types of ball cages for these guides, depending on the required needs:

Aluminum Ball Cages

Aluminum cage with hardened and ground steel balls of the highest quality. They have a much lower weight than other types of materials. Due to the fact that the ball cage has a purely supporting function, the reduction in weight, at the same stability, supposes lower mass forces, especially at the points of reversal of movements. The negative effect of cage displacement that occurs with large stroke movements is substantially reduced, resulting in increased guideway life. They are suitable for temperatures of more than 80ºC. They can be equipped with a safety ring according to Din 471.

brass ball cages

Made of brass with tempered and ground steel balls of the highest quality. They have a high mechanical resistance, the best sliding properties and a high resistance to wear. Due to their optimal thermal conductivity they are suitable for temperatures above 80ºC.

Plastic ball cages

Made of Hostaform C plastic material, with tempered and ground steel balls of the highest quality. Its heat resistance reaches 90ºC. Plastic ball cages are distinguished by having less mass than those made of other materials. This allows them to be highly indicated for those applications in which very high working speeds are required. These cages are also suitable for working in very aggressive environments.

Precision roller guides

Steinel precision roller guides can be used in all kinds of positions for longitudinal movements. Rotational movements are not possible.

A roller can support a load 8 times higher than a ball of the same size. In the following link you will find the catalog of roller cages:

Roller guides

The barrel-shaped contact radii are arranged in such a way that critical deformations in the angular area are avoided, which positively affects their performance. The deflection due to the load in the center and the seat in the external slide rails produces a swing less than 0.05 µm, which is a negligible value.

With optimal use, the travel speed can be 40 m/min and higher.

The rollers are placed in free movement in the housing holes. The rollers are arranged spirally in the axial direction, so that each roller has its own raceway.

The radial resistance of the guide increases with the prestressing, while the ease of sliding decreases. In any case, excessive prestressing overloads the guide due to excessively high surface pressure from the rollers. The prestress should be 2-4 µm.

These guides also allow the use of a limiting sleeve or stop to limit the travel of the cage on the column.

Steinel roller guides are virtually maintenance free. Proper lubrication at assembly is sufficient for correct long-term operation.

Aluminum roll cages are distinguished by their low weight. Said weight reduction, for the same stability, means lower mass forces, especially at the reversal points of the movements. The negative effect of roller cage displacement that occurs with large stroke movements is substantially reduced, resulting in increased guideway life.